The Millenium V4 Dual line is equipped with a heavy-duty six axis robot arm that can handle heavy panels at high speeds with exceptional precision.

It measures all panels as they enter the conveyor belt, and the suction cup grippers are adjusted on-the-fly to match the panel size, removing the necessity for manual adjustments. The alignment system installed in the Millennium V4 Dual detects panels on the conveyor and picks them up with precise alignment, eliminating friction between the conveyor rollers and the PCBs (contact-free alignment system).

The system can function with or without plastic interleaf by simply activating the relevant function. In its standard configuration, it is equipped with two loading or unloading stations and has a non-stop feature, enabling seamless switching between loading/unloading from station No.1 and loading /unloading from station No.2 without interrupting production.

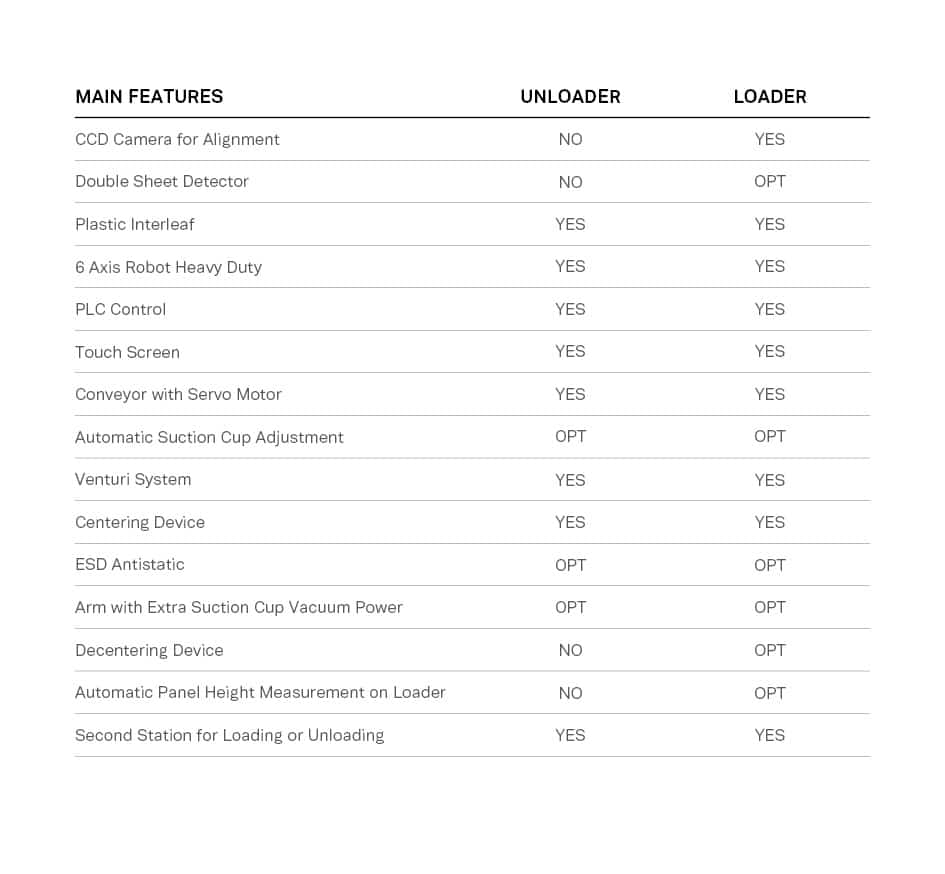

All Millenium V4 Series units can be further customized with a wide array of options, including a copper thickness measuring system, core thickness measurement, QR code laser engraving, double sheet detectors, and automatic panel height adjustment, among other features.